- Introduction: The Unseen Revolution in Power

- What Are AC/DC Power Supplies? The Essential Transformer

- Power Supply Technology: The Key Drivers of Change

- Why 2025 Is a Turning Point for Power Supply Technology

- Trend 1: Wide-Bandgap Semiconductors — GaN and SiC Take Center Stage

- Trend 2: Smart Digital Controls and IoT Integration

- Trend 3: Higher Power Density — Big Power, Small Footprint

- Trend 4: Market Growth Fueled by AI, Telecom, EVs and Automation

- Trend 5: Sustainability and the “Efficiency-First” Mandate

- Challenges Still Ahead: The Roadblocks to 2025

- Conclusion: What This Means for You

- FAQ — Frequently Asked Questions

Introduction: The Unseen Revolution in Power

AC/DC power supplies are what we might call the unsung heroes of our modern world. They are the essential, universal components transforming raw wall power into the usable DC voltage required by everything from your phone charger and laptop to industrial controllers and EV charging stations.

However, 2025 is shaping up to be a milestone year, marked by rapid technological shifts that are fundamentally redesigning how these components are built, how they perform, and where they are deployed.

This article breaks down the most critical trending technologies and market shifts in AC/DC power supplies. We will explain these changes in clear, accessible terms, revealing why these advancements matter significantly for technology developers, the manufacturing industry, and also everyday consumers.

What Are AC/DC Power Supplies? The Essential Transformer

At their most fundamental, AC/DC power supplies serve a simple yet critical function: they act as a transformer, converting the high-voltage Alternating Current (AC) delivered by the electrical grid (what comes out of your wall socket) into the lower-voltage Direct Current (DC) required by virtually all modern electronic devices.

These components are essential not just for conversion, but for delivering stable, reliable energy to sensitive circuits. They are responsible for precisely managing power flow while meeting varying voltage and current demands, whether they are powering a tiny sensor in a smart home or a massive rack of servers in a data center.

Power Supply Technology: The Key Drivers of Change

Power supply innovation has been a steady process for decades, but 2025 marks a period where several major trends are converging, leading to genuinely transformative change. The shift is being driven by a perfect storm of technical needs and massive market forces:

| Technical Driver | Market Impact |

| Demand for higher efficiency and significantly lower energy waste | Driven by global energy costs and sustainability goals. |

| Smaller, lighter form factors | Essential for compact consumer devices and crowded industrial cabinets. |

| Integration of smart control and monitoring technologies | Required for modern, automated industrial and grid systems. |

| Use of advanced semiconductor materials | Enables higher performance and smaller sizes. |

These technical evolutions are being heavily influenced by massive market forces, primarily the rapid growth of AI infrastructure, Electric Vehicles (EVs), industrial automation, and stringent energy-savvy regulations.

Let’s unpack these trends so you understand not just what is happening, but why these changes fundamentally matter for the next generation of electronics.

Why 2025 Is a Turning Point for Power Supply Technology

While power supply innovation has been a steady climb for decades, 2025 represents a steep acceleration. We are moving away from “good enough” technology toward high-performance systems. This shift is driven by a few major pillars:

- The War on Energy Waste: Efficiency is no longer just a nice feature. With rising electricity costs and stricter global “Green” regulations, manufacturers are under immense pressure to squeeze every bit of usable energy out of the grid with minimal heat loss.

- The “Smaller is Better” Directive: Whether it’s a sleeker laptop brick or a more compact industrial control cabinet, the demand for higher power density (more power in less space) is at an all-time high.

- Intelligence at the Edge: Modern power supplies are becoming “smart”. By integrating digital control and monitoring, they can now “talk” to a system, reporting on their health and energy usage in real-time to prevent downtime.

- The Semiconductor Revolution: The traditional silicon chip is reaching its physical limits. 2025 is the year where advanced materials like Gallium Nitride (GaN) and Silicon Carbide (SiC) move from expensive niche products to the industry standard.

- The AI and EV Boom: Massive market forces are pulling technology forward. The hunger for power in AI data centers and the rapid rollout of EV charging infrastructure are forcing engineers to rethink power delivery from the ground up.

Let’s unpack these trends even further so you understand not just what is happening but why it matters.

Trend 1: Wide-Bandgap Semiconductors — GaN and SiC Take Center Stage

If you’ve noticed that laptop chargers have become significantly smaller recently, you’ve already seen the Wide-Bandgap (WBG) revolution in action. For decades, Silicon was the king of the industry. But as we demand more power in smaller spaces, silicon is reaching its physical limits.

Enter Gallium Nitride (GaN) and Silicon Carbide (SiC).

What Makes GaN and SiC Special?

Think of these materials as the “super-semiconductors.” While silicon struggles with heat and speed, WBG materials thrive. Here is why they are superior:

- Lightning-Fast Switching: They can turn on and off much faster than silicon. This allows for smaller internal components.

- Drastically Less Heat: Because they are more efficient, they lose less energy as heat. Less heat means you don’t need bulky fans or heavy heat sinks.

- Higher Power Density: You can pack more “juice” into a smaller package.

- High-Temperature Resilience: They can operate in extreme environments where traditional silicon would simply melt or fail.

The Division of Labor: GaN vs. SiC

While both are better than silicon, they have different jobs in the 2025 market:

- GaN (Gallium Nitride): This is the star of the consumer and mid-power world. It’s why your new USB-C “brick” can charge your phone, tablet, and laptop at the same time while still fitting in your pocket.

- SiC (Silicon Carbide): This is the heavy lifter. SiC is built for high-voltage environments. You’ll find it in Electric Vehicle (EV) inverters, large-scale industrial motor drives, and renewable energy systems like solar farms.

In fact, research shows a large percentage of the power supply market (specifically in data centers and automotive sectors) is expected to transition almost entirely to WBG technology by the end of the decade.

Trend 2: Smart Digital Controls and IoT Integration

For a long time, power supplies were essentially “dumb bricks”: you plugged them in, they converted power, and you didn’t think about them again until they stopped working. In 2025, that is changing. Power supplies are evolving into intelligent, connected nodes within a larger digital ecosystem.

What Does “Smart” Actually Mean?

In the past, power supplies used analog circuits that were fixed. If you wanted to change how the power supply behaved, you had to change the physical components. Today, Digital Power uses software and microprocessors to manage energy.

Modern AC/DC units are now increasingly equipped with:

- Digital Control Architectures: These allow the unit to make precise, micro-second adjustments to voltage and current. This ensures the device receiving the power gets exactly what it needs, even if the load changes instantly.

- IoT Connectivity & Remote Monitoring: Many industrial units now feature communication ports (like Ethernet or Wi-Fi). This allows engineers to monitor heat levels, fan speeds, and energy consumption from a dashboard miles away.

- Predictive Maintenance: This is the holy grail for B2B. Smart power supplies can analyze their own performance data to predict when a component might fail. Instead of a factory line stopping unexpectedly, the system sends an alert: “I’m running too hot! replace me during the next scheduled break!”

Why This Matters for Business

This evolution is a massive cost-saver. By having a window “inside” the power supply, companies can manage energy loads more efficiently, reduce electricity bills, and prevent expensive downtime before it disrupts operations.

Trend 3: Higher Power Density — Big Power, Small Footprint

Thanks to the GaN/SiC materials and the precision of digital controls, we are seeing a massive shift in Power Density. In simple terms, power density is the art of packing more watts into fewer cubic inches.

Power supplies are shrinking, but their output is growing. This isn’t just about making things look sleeker, but about solving major engineering bottlenecks.

Why “Shrinking” Changes the Game

Higher power density offers several ripple-effect benefits:

- Saving Expensive Space: In a massive data center, floor space is incredibly expensive. If you can shrink the power supply, you can fit more servers into the same room.

- Reduced Material Costs: Smaller units require less copper, less plastic, and fewer raw materials. This can lead to lower manufacturing costs and a smaller environmental footprint.

- Thermal Efficiency: In the past, “small” meant “hot.” But because modern high-density units are so efficient, they generate less waste heat. This reduces the need for bulky, noisy cooling fans and heavy metal heat sinks.

Where Every Millimeter Counts

Smaller, high-density units are especially valuable in fields where space and weight are the primary constraints. Specifically:

- Medical Technology: Portable ultrasound machines and bedside monitors need to be light and compact without sacrificing reliability.

- Edge Computing: As we put more AI processing power in the field (like inside a smart traffic light or a 5G tower), the power supply has to fit into tiny, weather-sealed enclosures.

- Robotics & Drones: In these applications, every gram of weight saved translates directly into longer battery life and better agility.

Trend 4: Market Growth Fueled by AI, Telecom, EVs and Automation

The shift toward advanced AC/DC power supplies isn’t just a technical choice, but an economic necessity. As the world electrifies and digitizes, the power supply has become the critical bottleneck that these massive industries must solve.

The Heavy Hitters Driving Demand

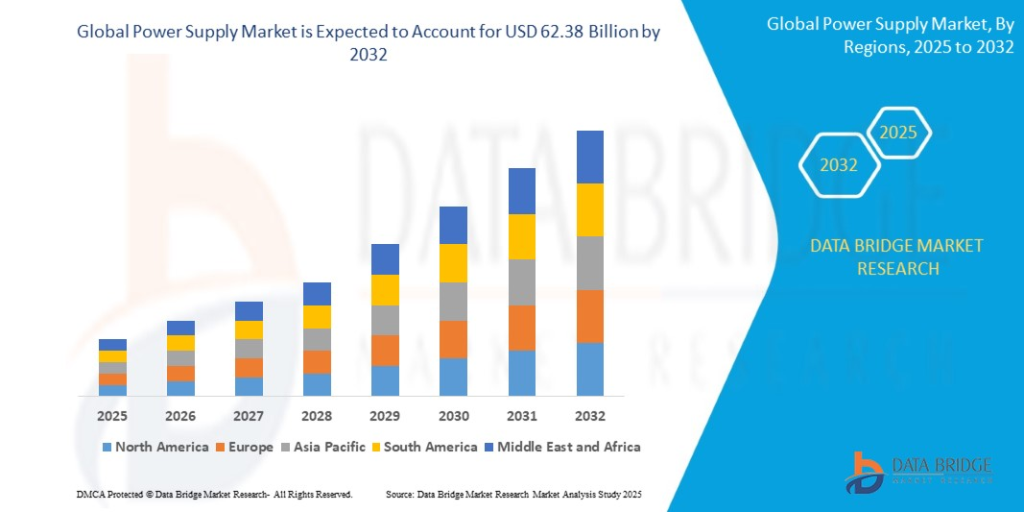

According to recent industry analysis, the global power supply market is forecast for significant growth between 2025 and 2032.

“The global power supply market was valued at USD 39.49 billion in 2024 and is expected to reach USD 62.38 billion by 2032.”

(Source: Data Bridge Market Research)

This growth is fueled by four specific sectors:

- AI Data Centers: Artificial Intelligence is “power-hungry.” To run the next generation of LLMs, data centers need power supplies that can handle massive, fluctuating loads without wasting energy as heat.

- Telecom & 5G-Plus: As 5G infrastructure expands into more remote and compact locations, there is a desperate need for small, weather-resistant, and highly efficient power units.

- Electric Vehicles (EVs): Beyond the car itself, the charging infrastructure requires high-power AC/DC conversion that is both fast and safe.

- Industrial Automation (Industry 4.0): Smart factories rely on 24/7 uptime. They need power supplies that don’t just work but also communicate their health to the network.

The New Standard of Requirements

In these high-stakes sectors, a standard power supply is no longer enough. The market is now demanding units that are:

- Ultra-Reliable: In a data center or hospital, a power failure is a catastrophe.

- Efficient Under “Varying Loads”: Modern systems don’t run at 100% all the time. Power supplies must stay efficient even when the system is idling.

- Communication-Ready: They must integrate seamlessly into centralized monitoring systems.

The Bottom Line: Even as competition in the electronics market increases, high-quality AC/DC power supplies remain the essential building blocks of the digital and electrified world.

Trend 5: Sustainability and the “Efficiency-First” Mandate

In 2025, power supplies are no longer judged solely on raw performance. With global energy prices fluctuating and environmental regulations tightening, the focus has shifted toward extreme efficiency and sustainability.

The New Rules of the Game

Regulatory bodies are setting the bar higher than ever. Manufacturers must now navigate a complex landscape of standards:

- The “Common Charger” & EU 2025/2052: New European regulations (specifically Regulation EU 2025/2052) are now in full effect. They don’t just demand higher efficiency, they mandate interoperability. Most external power supplies must now use USB Type-C and detachable cables, significantly reducing electronic waste.

- The Rise of 80 PLUS Ruby: While “Gold” and “Platinum” were once the peak, 2025 has seen the introduction of the 80 PLUS Ruby standard. Designed for high-end data centers, this level requires an incredible 96.5% efficiency. This means only 3.5% of the energy is lost as heat.

- Zero-Waste Standby: New “no-load” power consumption limits mean that even when a device is turned off, its power supply must draw virtually zero energy from the wall.

Efficiency as a Business Strategy

For B2B specialists, sustainability is now a key part of the Total Cost of Ownership (TCO). Choosing a high-efficiency power supply is now about:

- Lower Utility Bills: In massive industrial plants or data centers, a 2% increase in efficiency can save thousands of dollars in annual energy costs.

- Extended Lifespan: Less heat waste means less stress on internal components like capacitors. Highly efficient units simply last longer, reducing replacement costs.

- ESG Compliance: Many companies now have strict “Environmental, Social, and Governance” (ESG) goals. Using energy-certified power supplies is an easy win for corporate sustainability reporting.

The takeaway: In 2025, efficiency is as much a market priority as it is a technical one. If it’s not efficient, it’s not competitive!

Challenges Still Ahead: The Roadblocks to 2025

Even with these exciting trends, the power supply industry is navigating some significant “growing pains.” For B2B specialists and manufacturers, these are the hurdles to watch:

- The “GaN Premium” & R&D Costs: While the price of Gallium Nitride (GaN) and Silicon Carbide (SiC) is falling, these materials still require a higher upfront investment in research and manufacturing retooling compared to traditional silicon. For cost-sensitive projects, silicon is still the better option.

- Geopolitical & Raw Material Fragility: The supply chain remains a major headache. Recent export restrictions on critical minerals like gallium and germanium, combined with mounting concerns over copper supply due to climate-related mining disruptions, have made sourcing more volatile and expensive.

- The Engineering “Skills Gap”: Designing a smart power supply isn’t just about hardware anymore, because it requires software expertise too. Currently, there is an unprecedented shortage of electrical engineers. In some regions, one in three engineering roles remains unfilled as students flock toward computer science instead of power electronics.

- The Heat Paradox: As we pack more power into smaller boxes (Trend 3), managing thermal stress becomes incredibly complex. Even high-efficiency units generate some heat, and in ultra-compact designs, that heat has nowhere to go without expensive advanced cooling solutions like liquid cooling or specialized heat sinks.

Conclusion: What This Means for You

Whether you are a device designer, an industrial engineer, or simply a tech enthusiast, 2025 promises a power supply landscape that is smarter, more efficient, and more capable than ever before. We are moving away from the era of “passive hardware” and entering the age of intelligent energy management.

This evolution is being spearheaded by the materials revolution, where wide-bandgap semiconductors like GaN and SiC have transitioned from future tech to the current industry standard, allowing us to shrink devices while simultaneously boosting performance.

This hardware shift is complemented by the fact that intelligence is now standard. With the integration of smart digital controls and IoT connectivity, modern power supplies have become proactive systems capable of predicting their own maintenance needs.

These innovations are being propelled by powerful market synergies, as the explosion of AI, EVs, and 5G infrastructure provides the economic fuel necessary to keep innovation moving at record speeds.

Ultimately, this progress is green by design, ensuring that sustainability is a core part of the engineering process that helps businesses lower both their carbon footprints and their utility bills.

Which trend do you think will have the biggest impact on your industry? Are you more excited about the shrinking size of hardware or the new intelligence of digital power? Share your thoughts in the comments below!

FAQ — Frequently Asked Questions

Q1: What is the main difference between AC/DC and DC/DC power supplies?

A: It’s all about the source. AC/DC supplies take power from the grid (your wall socket) and turn it into usable DC power. DC/DC converters take that DC power and “step it up” or “step it down” to the specific voltage needed by different internal components, like a processor or a fan.

Q2: Why is everyone talking about GaN and SiC?

A: Because they are “super-materials.” Unlike traditional silicon, they handle heat better and switch power much faster. This allows engineers to build power supplies that are 3x smaller and significantly more energy-efficient.

Q3: How does “IoT Integration” actually help me?

A: It gives you a dashboard for your power. Instead of waiting for a machine to break, you can remotely monitor temperature and energy use. This allows for predictive maintenance, meaning you can fix a problem before it causes a costly shutdown.

Q4: Is this next-gen technology expensive?

A: Initially, yes. High-end GaN and SiC components carry a price premium. However, as production scales in 2025 and the technology matures, the total cost of ownership often ends up lower because you save so much on energy and space.

Q5: Can I find these trends in my everyday electronics?

A: Absolutely! If you have a modern, ultra-slim laptop charger or a fast-charging brick for your phone, you are likely already using GaN technology. These industrial trends always find their way into our pockets eventually.